The BMW M1 is one of the car manufacturer’s most iconic models and one is currently up for auction through Bring A Trailer.

BMW famously developed the M1 as a homologation special so it could compete in the FIA Group 5 championship. They had to build 400 road-going cars to comply with for Group 4 standards and did just that (actually, they built 453). This example looks to have been well-maintained and is being sold with a clean Montana title and the odo shows just 6,800 km (~4,200 miles).

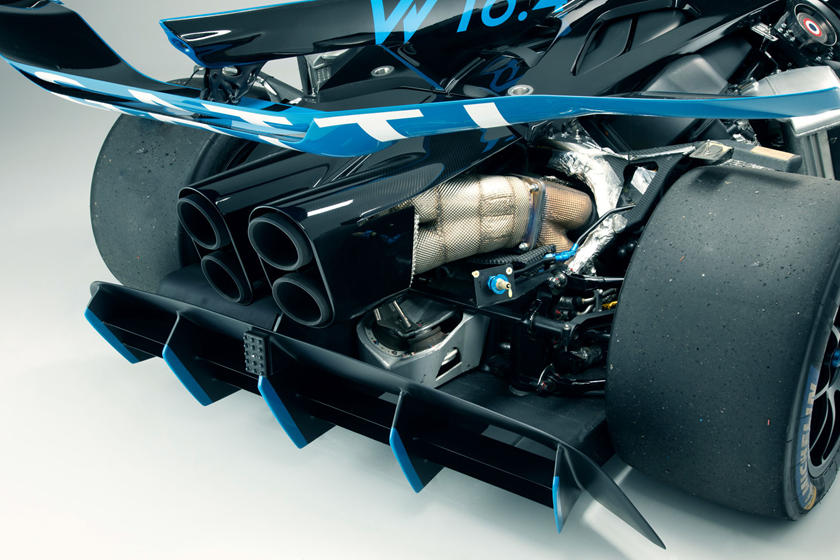

This M1 was delivered new in August 1979 to BMW Schneider in Bielefeld, Germany and in the early 1980s, was modified by BMW dealer AHG and outfitted with their Studie package that saw it repainted with a BMW tricolor livery and fitted with new aerodynamic panels inspired by the M1 race cars. The Studie package also added three-piece BBS wheels, a custom exhaust, and full-leather upholstery on the seats.

After being imported to the U.S., the car was part of a Georgia collection until 1995. It was purchased by a Texas collector in 2011 and then added to the AE Performance collection shared by the late Paul Walker and Roger Rodas in California, before being acquired by its current owner in 2014.

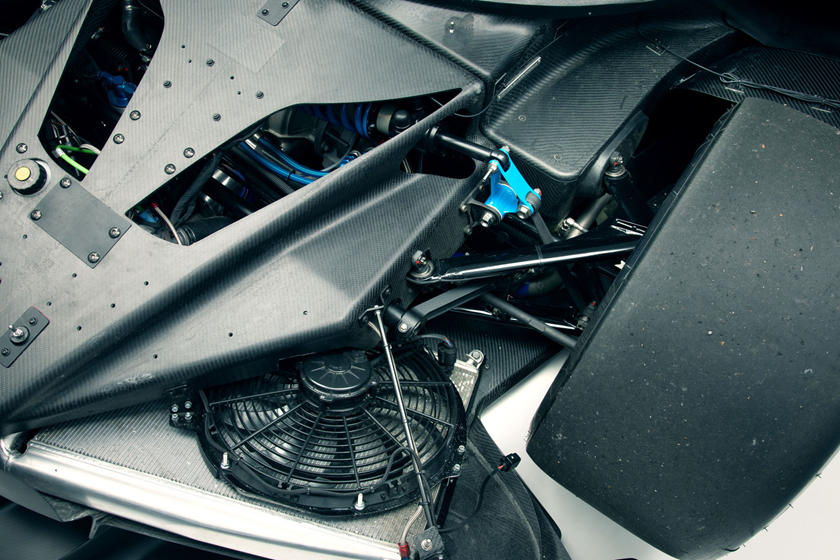

Power is provided by a 3.5-liter inline-six with Kugelfischer-Bosch fuel injection, Magneti-Marelli ignition and six individual throttle bodies that is coupled to a ZF five-speed manual transmission with a limited-slip differential. Typical road-going M1s were rated at 277 hp but cars from AHG were massaged to 350 hp. The listing reveals that this car had a service performed in August 2018 that saw the oil replaced, coolant flushed, and a new battery installed.

At the time of writing, bidding had reached $350,000 with 10 days left in the auction.

PHOTO GALLERY